Hydraulic & Pneumatic Products

Brochure

Download our document to see specific data of the service and how we work.

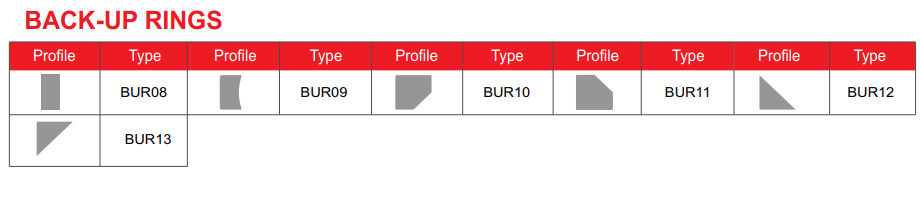

Back Up Rings

Back-up rings, or anti-extrusion rings, are thin rings that are designed to prevent O-ring extrusion under pressure. They fit in the gland between the seal and the clearance gaps to provide zero clearance. Read on to find out more about the function of these invaluable parts. Back-up rings provide added resistance support to a seal and minimise the risk of extruding a seal in its housing when under pressure. Back-up rings, sometimes known as anti-extrusion rings, are not designed to have any sealing function in their own right. They are simply there to support the actual sealing elements of a design and stop them extruding under higher pressures, or where metalwork clearances are larger than is ideal. Back-up rings for O Rings can be contoured or flat, depending on the design requirements of the sealing system.

They can come in the form of a solid ring, a split ring or even a spiral ring, depending on the environment that the back-up ring is expected to operate in, and for ease of fitting. Extrusion under pressure can happen to almost any type of seal, not just O Rings, Back-up rings are placed behind the seal if it is a single acting system, or both sides if double acting. Back-up rings are always made of a harder material than the seal itself to minimise the amount of extrusion in the sealing gap of the seal housing. They do this by supporting the sealing element itself with a close fit to the housing. When greater sealing and system forces are anticipated, the more precise the fit of the parts must be.

Consideration must always be given to the environment expected for any particular seal and its back-up rings. It is also important to consider the degree of acceptable friction losses, in order to provide the most suitable solution, as a back-up ring may increase the friction present within a system.